A Guide to Burs

Overview

Dental burs, the tiny drill pieces for teeth! Dental burs are used in conjunction with the handpiece to cut and polish the dental surface, cutting away hard tissue such as tooth and bone, as well as to remove carious tissue.

Dental burs are composed of three main parts (Shank, neck and head). Among the different types of burs (steel, hardened steel and hard steel) we can find there are both the US numbering system and the ISO numbering system.

There are a huge range of burs, with different materials, shapes and sizes to suit different situations and procedures. This bewildering range of options can leave you confused and unsure of what bur you require. If you are not clear on how to choose burs, we have listed the most common ones below.

Best Practice of Dental Burs

Burs are normally used in high-speed handpieces. Best practice is to dispose of burs between each patient to reduce turbine wear of the high-speed handpiece. They should not be used for more than 3 patients for risk of potential damage to the high-speed handpiece/turbine.

Here are a few general tips from our suppliers to help you improve the life and longevity of your burs:

- For the safety of user and patient, it is highly recommended that only dental specialists should work with dental burs.

- Attention should be paid to speed of work (RPM). Using a bur with too high RPM level, could generate undesirable heat.

- Do not force a bur into the turbine. In case of difficult access, check both turbine and bur. Special attention should be paid to instructions of use and maintenance of the turbine.

- dental burs are designed for several uses and are autoclavable.

- Sterilize the burs before use.

Shapes

There is daunting range of shapes available which can make it extremely hard to decide which suits your situation best. Different flute angles create different cutting characteristics, making each bur appropriate for a particular task. Operative (cavity preparation) burs have deep and wide flutes to allow for more aggressive enamel cutting. These burs will usually be straight bladed or crosscut. Trimming and finishing burs will have more blades that are closer together and much shallower making them perfect for fine finishing and polishing. The most used bur head shapes include round, pear, cross-cut tapered fissure, cylinder and inverted cone.

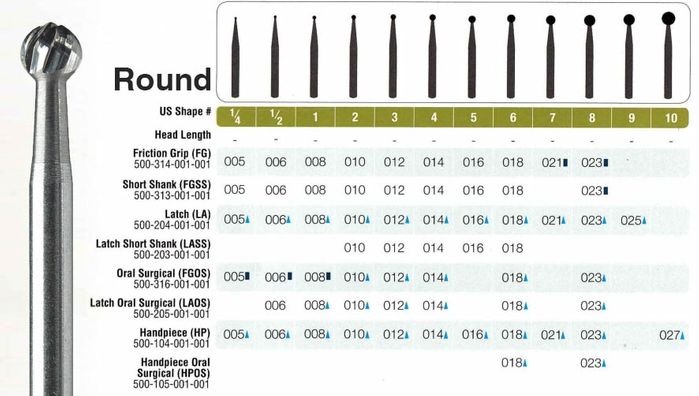

Round BursRound burs are useful for creating access holes, removing buccal bone, creating a moat around root fragments, and smoothing alveolar bone. They are available in short, regular and surgical length shafts and have tip sizes that range from ¼ to 10. Some recommended round burs for veterinary dentistry are the ¼, ½, 1, 2 & 4 for cats and small dogs and the 2, 4 & 6 for medium and larger. Round burs come in a size range from ¼ to 10. |

|

Veterinary ApplicationsRound burs can be used for:

Smaller head diameters can help create ultra-conservative preparations.

|

|

Pear BursPear shaped burs are useful for sectioning teeth, removing buccal bone, creating moats around root fragments, and smoothing alveolar bone. Both the tip and the side of the head on these burs can be used, which is what makes them so versatile. Some pear burs are available with a longer cutting surface (L) and all of them are available with a short or regular shank. Some recommended pear shaped burs are the 329 and 330 for cats, and the 331 for dogs. |

|

Veterinary ApplicationsPear burs are used for:

Pear shaped burs have a rounded edge unlike inverted cones. To look at our product range, Click Here

|

|

Cross-cut Tapered Fissure BursCross-cut burs have more cuts in the blade to create a more efficient cutting process, cutting much quicker due to less debris build up. |

|

Veterinary ApplicationsCrosscut tapered fissure burs can be used for:

To look at our product range, Click Here

|

|

Finishing BursFinishing burs are used for finishing restorations, soft tissue re-contouring, enameloplasting & odontoplasty. Finishing burs can be obtained as 12 or 30 bladed burs in carbide or diamond head in a variety of shapes. Finishing burs are also available in white stone for composite and green stone for amalgam. |

|

ShanksShanks make up the long part of the bur piece below the tip. Shanks have different ends to attach to different types of handpieces and are available in different lengths to enable attachment to specific handpieces. There are also standard length and "surgical" burs. The difference is the standard lenght is 20mm, the surgical is 25mm for better visibility and reach. |

|

|||||||||||||||||||||||||||||||||

|

Long Straight Shank (HP)Long and extra long straight shanks (45mm and 60mm) are used on slow speed handpieces with a 1:1 straight nose cone, most commonly used for diamond cutting discs. Long straight shanks are also used in surgery procedures. These burs can drill through thick bone for surgical, orthopaedic and endodontic procedures. Find our range of long straight shank burs here.

|

Latch-type Shank (RA)This type of shank is generally of 19mm or 20mm in length with a 2.35mm diameter and fits in low speed handpieces and contra angles. Latch-type shanks often available with the same shapes as Friction grip shanks. Find our range of latch-type shank burs here. |

Friction Grip Shank (FG)Friction grips are used in conjunction with carbide and diamond head burs. Friction grips are used with high speed handpieces and like latch-type shanks they are generally around 19mm or 20mm in length with a 1.6mm diameter. Find our range of frition grip type shank burs here. |

||

Bur Materials

Burs are available in a range of materials. Each material has its pros an cons, making them suitable for different tasks.

Have a look at the different types of bur materials below:

|

Diamond BursDiamond burs are most commonly used with high speed handpieces, meaning they are most commonly available as a friction grip shank. Diamond is the hardest material available and is used to grind away tooth tissue, usually enamel. The grinding motion of a diamond bur leaves a rough finish. Diamond burs have a short lifespan due to a pronounced decrease is cutting effectiveness. Diamond burs often get clogged with debris, the grinding motion also quickly wears down the instrument. Diamond burs come in an array of shapes and are available in a range of grits; from ultra fine to super coarse. When cutting away porcelain restorative material diamond burs are very effective. |

Carbide BursCarbide burs are made of tungsten carbide, a material that is 3 times stiffer than steel. Because of it is such a hard material it is able to maintain sharpness, making it an effective cutting tool. Much like diamond burs, carbide burs are available in a variance of shapes. The cuts made in the head of the bur make them effective cutting instruments as there is very little build up in debris. Carbide burs cut and chip away the tooth structure rather than grinding as diamond burs do, this leaves a much smoother finish than diamond burs. Carbide burs are better handling for removing metal based restorations, they are also effective for trimming and finishing macro-filled and hybrid composites. Carbide burs are most commonly available as a friction grip shank but RA latch type shanks are also widely available. |

Steel BursSteel burs provide an economical solution used for cavity preparation and dentine removal. Steel burs are softer, more flexible and also more resistant to chipping and breaking than carbide burs, although they’re more flexible this does make them blunt quicker than a carbide bur. Steel burs are most commonly available with a latch type RA shank but are also available with friction grip burs. |

||

Numbering System

Due to the huge array of shapes and sizes of burs standard numbering systems where put in place to easily identify burs. There are two main systems that are used; the U.S. and ISO (International Standards Organisation) numbering systems. The U.S numbering system is most commonly used for carbide burs and is generally a 1 to 4 digit number dependant on the bur.

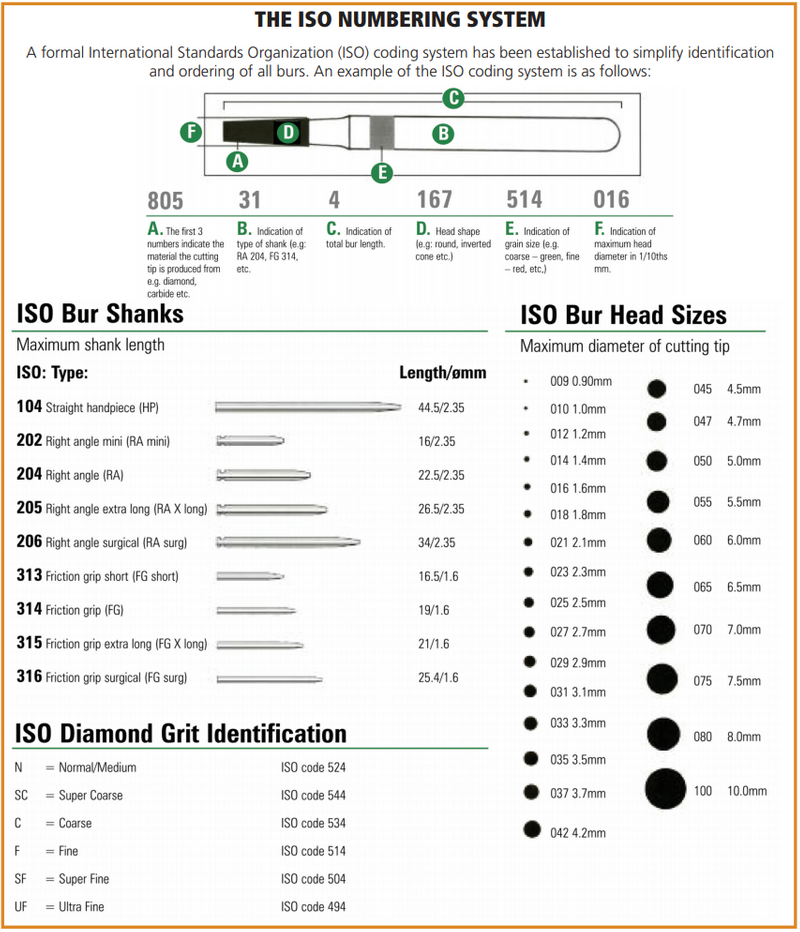

The ISO numbering system was introduced in 1979, labelling dental burs with a 15 digit code that are broken down into 6 sections:

|

A. Type of bur e.g. diamond/carbide

|

D. Head shape e.g. ball head

|

|

B. Type of shank e.g. straight (HP)

|

E. Indication of grit e.g. coarse/fine

|

|

C. Total bur length |

F. Size of maximum head diameter |

Source: Johnson Promident

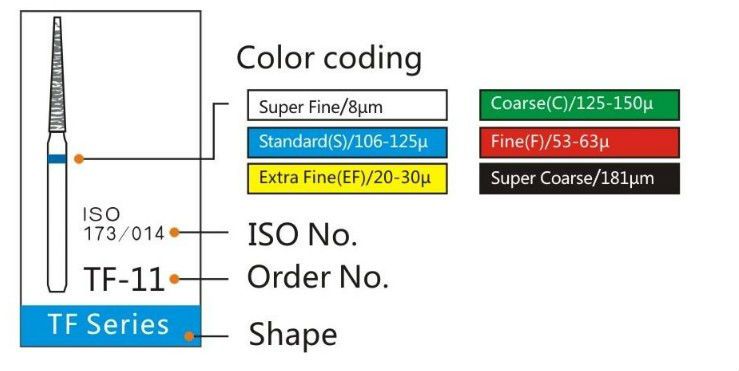

Diamond Grit Identification

The degree of roughness can often be identified by the colour of the dental bur. The roughness classification of dental burs is also standard, but is not reflected in all manufacturers or all types of burs. The classification for this is as follows:

White: Super fine

Yellow: Extra fine

Red: Fine

Blue: Standard (sometimes no colour)

Green: Coarse

Black: Super coarse